[S.L.E.D.]

Surface Linear Equalization Device

Every Maker or Woodworker, sooner or later, will build—or try to build—a cutting board. And after cutting, gluing, and assembling the wood, they’ll come face to face with a bitter truth: they don’t own a planer. Or worse—their planer is too small.

[S.L.E.D.] solves that problem.

Thanks to a set of well-thought-out and engineered solutions, it goes beyond the basic function of a sled. It does more. It becomes The First Modular Surfacing/Router Sled.

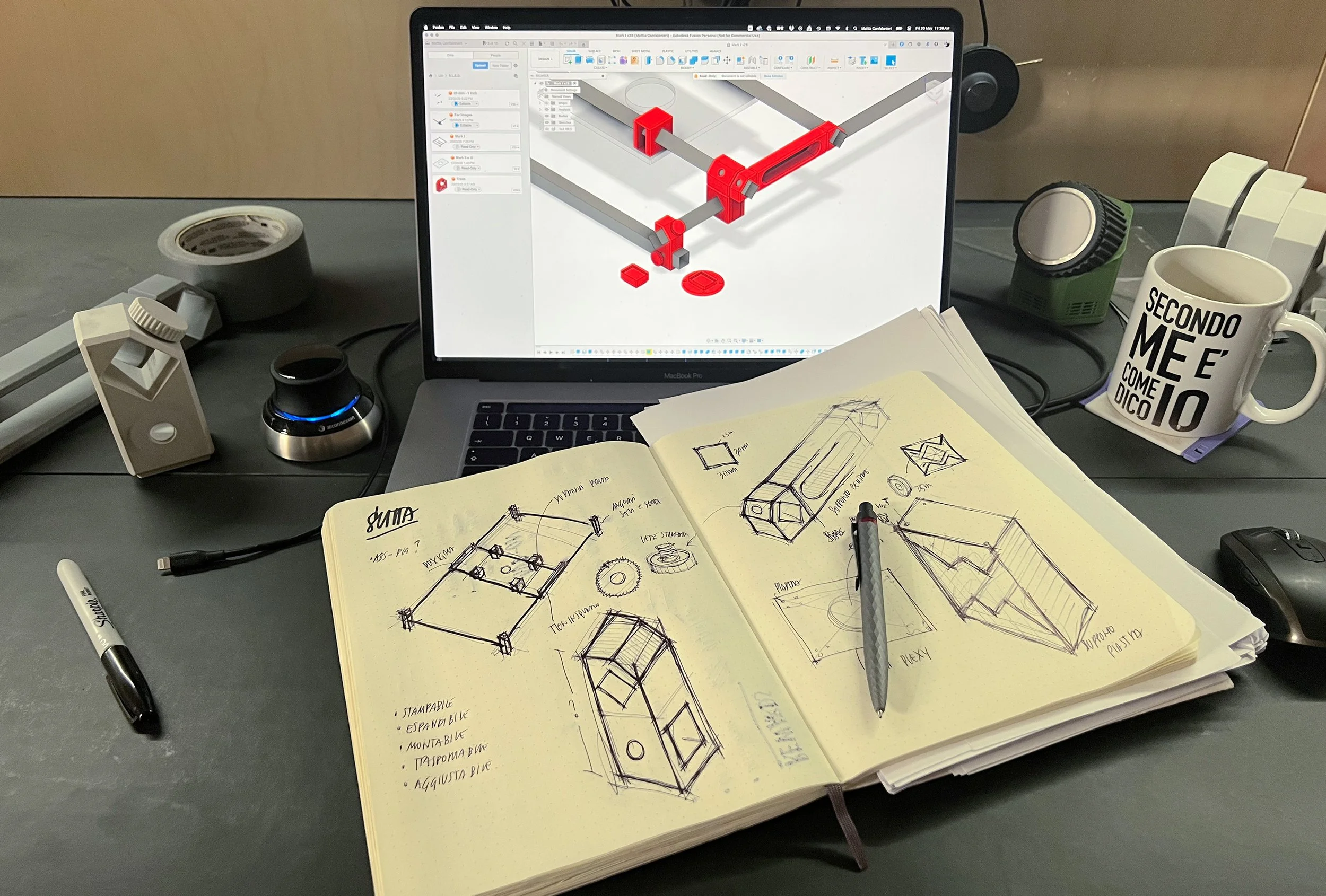

The idea was born from a specific need of mine. While working on a project, I had to surface a wooden piece much larger than what my planer could handle. A quick sketch, a few hours of printing, some PLA—and the first prototype was up and running.

Mark I - II - III

It wasn’t meant to be a prototype—it was just supposed to be an ugly but functional contraption to get the job done.

And it did work. I managed to complete the task I had. But it was thanks to that project—and the Instagram reel I shared—that I realized there was massive interest in what I had built, and that I wasn’t the only one facing that need.

Maybe it was worth taking it seriously.

The second prototype was a whole different beast. It cut down material usage by one-third, improved aesthetics, and simplified assembly.

However, it had some structural issues—maybe I had gone too light this time.

Now we were getting somewhere. Another one-third reduction in material use, but stiffness significantly increased thanks to a truss-based structure. It really looked like the final form.

Until they showed up... the international users.

The Final Form

Reading through the comments under the various reels I posted during the prototyping journey, I realized not only were there many others with the same need, but some had even more specific requirements.

And most importantly, many of them were from outside Italy—where they don’t necessarily use the metric system.

Sometimes, to move forward, you have to take a step back. And that’s what I did. Just when I thought I had the final prototype in hand, I went back to the drawing board: rotated the tubes 45 degrees, made the whole thing reversible to accommodate all possible heights, and most importantly—changed the tubing format so anyone could use what they had on hand, whether they measured in millimeters or inches.

A fully functional prototype in every aspect, ready for production.

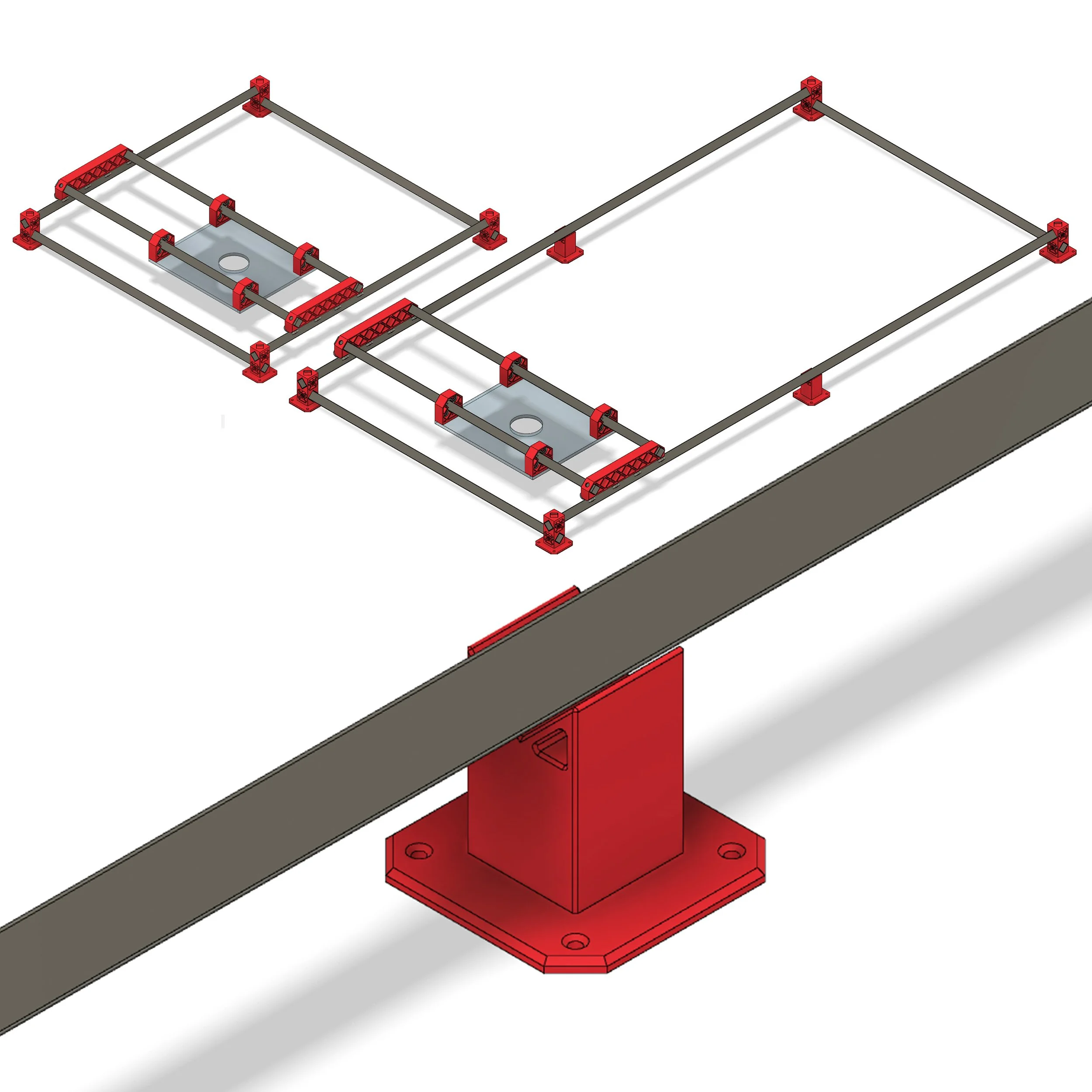

Expandable

[S.L.E.D.] adapts to the job you need to do—or to the space you have available.

How? Simple. No oddly shaped rails or proprietary tracks. Just basic 25x25mm

or 1-inch square tubes. The central supports do the rest, making it virtually infinitely expandable.

Whether you need it 1m x 1m or 1km x 1km—yes, really—it’s up to you.

Smooth

High-quality ball bearings make [S.L.E.D.] glide with smooth, effortless motion.

Double protective flanges and easy access keep dust and chips from being a problem. Maintenance? Just a quick blast of compressed air every now and then.

Eternal

Broke a part? Wore something out? Need one more Stop-Block or Central Support?

Just print it.

Multi-purpose

Maybe you don’t need to flatten a slab. Maybe you need a groove—or ten. Maybe you want to shape a pattern.

The Stop-Lock System lets you do all of that without even disassemble the [S.L.E.D.]. Fix a board, set a stop point... or two... or three... or four... or....

Democratic

Which filament to use? What color? How tough it should be? It’s all up to you.

Want it in hot pink? Go for it. I don’t judge.

From 0 to Hero

Thanks to its Modular Risers and Reversible Frame, [S.L.E.D.] covers all the bases.

Route from 0 height all the way to... whatever [not Giaco].

You could even mill the floor under it. Hey, maybe you want an inlay in your hardwood floor.

Affordable… or not

You decide the final cost: go cheap with steel tubing, spend a bit more for classic aluminum, or go all-in with CNC rails.

Heck, use Adamantium if you’ve got it lying around.